Coffee Cycle Roasting

Ethiopia Shantawene (250g) - Coffee Cycle Roasting

Ethiopia Shantawene (250g) - Coffee Cycle Roasting

Couldn't load pickup availability

Ethiopia Shantawene G1 Washed

Washing Station: Shantawene Washing Station by Tracon

Altitude: 2000-2200 masl

Variety: JARC 74165 & JARC 74110

Process: Washed

Drying: 11 Days on Raised Beds

From La Baia Coffee Importers:

"

Summary

Our experience over the years of sourcing from Shantawene, the coffees grown in these areas are really gaining traction for their success in the COE and are highly coveted around the world for their very high quality and unique flavor profiles. The Shantawene village is situated between the village of Bombe and the base of the Bombe mountain in the Sidama Region of southern Ethiopia.

While Ethiopia has gained great popularity around the world for their naturals, clean complex Ethiopian washed coffees are an absolute staple on any serious coffee menu. Coffee is an important cash crop in the region, and most farmers in the area are very aware of this reality. However, to further improve quality, the station pays premiums to smallholders to incentivize delivery of exclusively high quality and freshly picked red cherries to ensure that the majority of coffee comes from the farmers in the nearby villages of Shantawene and Bombe (meaning they haven’t spent a long time traveling to the station). Fresh cherry comes to Shantawene Station everyday, due to the prime location of the station farmers transport their coffee with horses and motor bike. Cherries usually arrive daily from 2 - 6pm. Shantawene is managed by Seid Mohamed and he oversees cherry selection, post harvest production and compensation distribution directly to the local farming partners.

PROCESSING

Once harvesting is underway they deliver directly to the collection site located at the Shantawene Station. The cherries are then evaluated based on several key factors: color, ripeness and density. The cherries are floated to remove any cherries designated as "floaters" to ensure only the cherries with the highest concentration of fruit mucilage and the highest degree of successful maturation has been achieved in both the fruit and cherry seed. Floating also assures the removal of inferior or hollow seeds and defects. At Shantawene they emphasize the use of traditional underwater fermentation that is popular in Ethiopia. In underwater fermentation the coffee is fully submerged in water for 48 to 72 hours normally, but the process can vary station to station. After fermentation the coffee is depulped and then dried for 11 days on raised drying beds. The first two days of drying are critical to the evolution and development of the coffee. The parchment is rotated consistently during the drying period to avoid uneven drying and consistent exposure to air and sunlight.

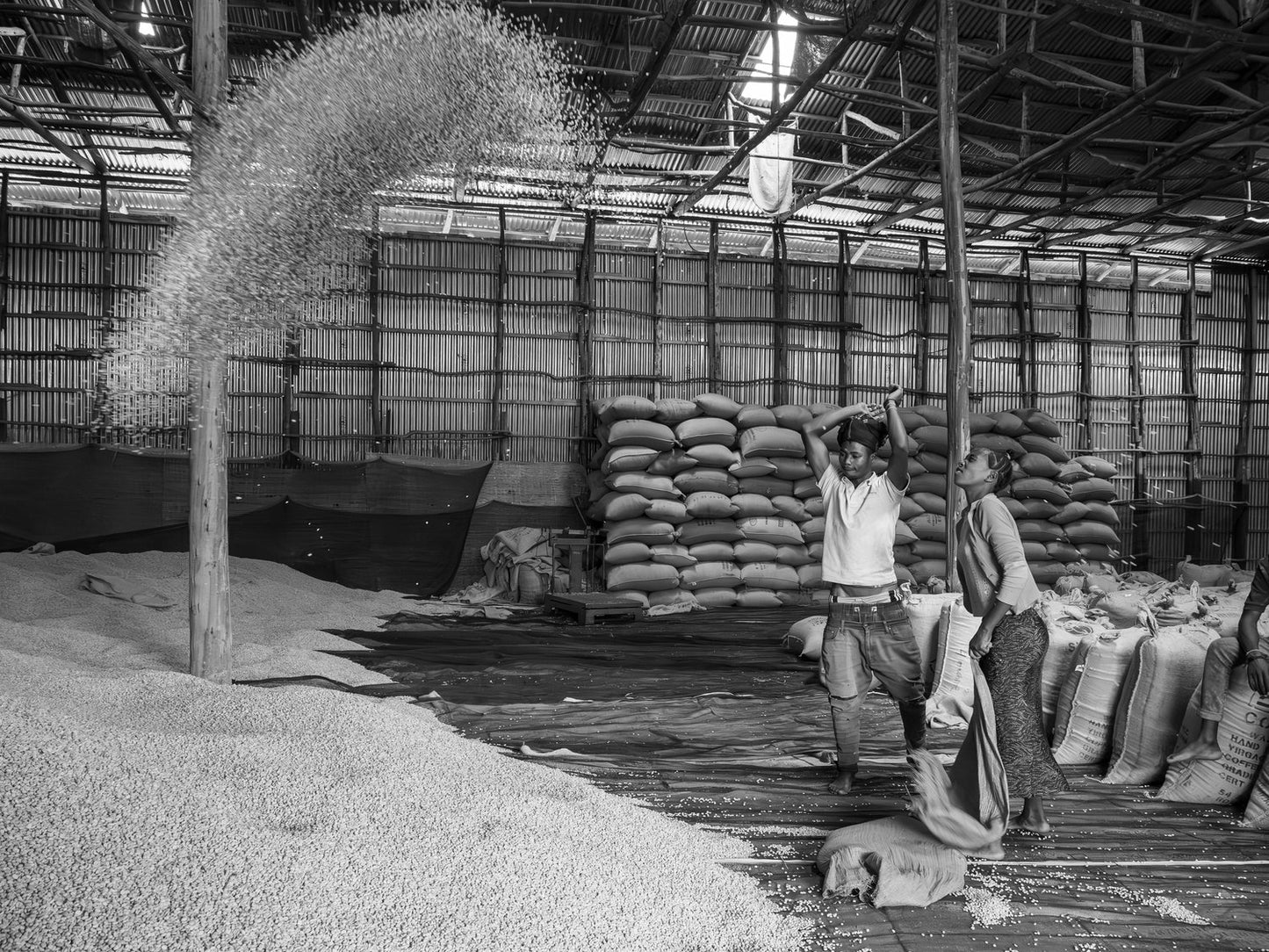

Tracon has developed a state of the art modern coffee cleaning and milling facility in Addis Ababa where the coffees are all transferred for final milling following the initial collection and post harvest production phase of all their coffee. The facilty is equipped with the latest Pinhalese coffee processing equipment to sort coffees by density, size and also utilize high level pieces of automated equipment like optical color sorters for final sorting. Each lot contracted with Tracon this year was done on a prebook basis prior to the coffee harvest. We believe embracing this model equips partners with the tools and resources to provide early harvest premium payments directly to farmers and to help producers mitigate and calculate risk knowing they have a secured buying partner on the other end to support their efforts.

JARC VARIETIES - CBD RESITANT SELECTIONS

Currently the majority of coffee produced in Ethiopia is produced from three production systems: forest, semi-forest, and garden coffee. The level of variation among coffee varieties in the forest and semi-forest production systems are recognized as a higher degree of quality than garden coffee production systems. Kurume is one of Ethiopia’s regional landrace varieties from Yirgacheffe. Farmers in Ethiopia have always had an interest in changing the genetic base of their varieties in different production systems in pursuit to improve coffee production and yield. The Jimma Agricultural Research Center (JARC) has made huge contributions to the global coffee community with its efforts over the past 40 years to expand knowledge through scientific research and studies in Ethiopia. In the efforts by the (JARC) to push towards revolutionizing the development of modern coffee varieties in Ethiopia they have created innovative methods to genetically combat CBD (coffee berry disease) and increase the overall efficiency in production and yield for coffees grown naturally in the forest and semi-forest production systems.

In 1971, coffee berry disease (CBD) was spreading throughout Ethiopia and likely had been around for years. Initial trials in 1972 used chemical-based fungicides to test prevention of the disease. While these proved successful, it was decided that a better solution would be to collect and use the broad genetic diversity of Ethiopian coffee to develop CBD-resistant varieties. The selection process for these varieties began in 1973 and resulted in collections from 19 locations in Southwestern Ethiopia. After collecting seeds from 639 different coffee trees originally collected in the areas of Gera, Metu-Bishari, Washi and Wush Wush for showing resistance against CBD. For 1974 and 1975 CBD resistant improved coffee varieties, if a variety name starts either with a 74 or 75 it is a selection number given to the variety and can represent a broader group of different varieties that stem from the 1974 and 1975 CBD Resistant Selection Group.

"

Share

Materials

Materials

Dimensions

Dimensions

Care information

Care information